The washing machine worked diligently for a long time, but on one unhappy day a strange noise in the process of spinning clothes at high speeds. Most likely the bearings have worn out and you need to respond to this as soon as possible in order to avoid wear on the housing.

The washing machine worked diligently for a long time, but on one unhappy day a strange noise in the process of spinning clothes at high speeds. Most likely the bearings have worn out and you need to respond to this as soon as possible in order to avoid wear on the housing.

Perhaps nothing terrible has happened and you only need to lubricate the bearings of the washing machine drum, which of course will significantly extend the life of the equipment. How to do it?

Choosing a lubricant for a washing machine

It is different and has distinctive characteristics. But, each of them must be:

- heat resistant, since the bearing and the oil seal during operation, the washing machines heat up when washing at a high temperature;

- moisture resistant. If water gets on the bearing, it will have to be replaced, because this is unacceptable. To prevent this situation from happening, an oil seal is needed. It is he who does not let moisture into the part. If the grease is washed out during the operation of the washing machine, the bearing will break;

- thick. This quality allows not to flow out when washing.

- not aggressive. Lubricant must be suitable for rubber.If it does not have the desired properties or is a poor-quality product, the oil seal may become dull or, on the contrary, get wet during its use. This again will lead to depressurization.

Do not use automotive lubricants (Litol-24, Azmol, etc.) due to their inefficiency.

What kind of grease for washing machine bearings to buy

Indesit washing machine manufacturers recommend using lubricant Anderol. You can buy either in a jar (100 g) or in a syringe.

Indesit washing machine manufacturers recommend using lubricant Anderol. You can buy either in a jar (100 g) or in a syringe.- There is a waterproof grease of Italian origin on the market Amplifon by Merloni.

- Good water resistance and heat resistance of the grease Staburags nbu12.

- German high quality silicone grease Liqui Moly Silicon Fet efficient but costly. Sold in 50 gr.

If you need to lubricate both the bearing and the oil seal, then a waterproof grease Huskey Lube-O-Seal PTFE Grease great selection and high quality.

If you need to lubricate both the bearing and the oil seal, then a waterproof grease Huskey Lube-O-Seal PTFE Grease great selection and high quality.- Kluber Staburags NBU12 sold up to 1 kg. It differs in that it retains viscosity up to a temperature of 140 degrees.

What and where to lubricate

Not many people know that care is required bearings, but the lubrication of the seals is required. There is usually grease in the bearings already.

If this part is original, made at the factory and bought in a specialized store, then you can put it in the washing machine without additional processing.

If this part is original, made at the factory and bought in a specialized store, then you can put it in the washing machine without additional processing.

Otherwise, dubious quality necessarily requires prior care, because cheap materials and lubricants are usually used, including. Better to update it yourself.

Washing machine disassembly

It is not possible to lubricate the bearing of a washing machine without disassembly, so the process of lubricating internal parts is laborious.

This is necessary in order to get a tank with a drum, in which the part we need is located. Before work, the equipment is de-energized and disconnected from the water supply. The washing machine is put in place with free access to it. You will need pliers and screwdrivers.

The top cover of the washing machine is removed, which is held on the back by two bolts.

The top cover of the washing machine is removed, which is held on the back by two bolts.- Pulled out compartment for detergents.

- The wires are disconnected from the board, and the control panel is disconnected.

- Using a slotted screwdriver, the clamp is removed, which is removed by pressing the spring. Then the edges

rubber bands are tucked into the drum, and cuff removed.

rubber bands are tucked into the drum, and cuff removed. - Remove the bottom panel. It is secured with snaps.

- Next, the front panel is removed. To do this, bolts are unscrewed behind the powder receiver.

All wires and pipes that fit the tank must be unhooked.

All wires and pipes that fit the tank must be unhooked.- Filmed pressure switch with wires and the front panel is pulled out.

- Both counterweights are removed to lighten the tank.

- Filmed tank from the springs, after unscrewing the shock absorbers. The tank is placed on the floor with the pulley up.

- The belt is removed from the engine, and then the engine itself.

If during operation something cannot be disconnected or removed, do not apply force. You can fill in soured screws with WD-40, and drill out broken ones.

Pay attention to the tank. There are two types: collapsible and solid. If you have a Hotpoint-Ariston washing machine, for example, then most likely the tank is non-separable.In this case, it will have to be cut to get to the bearings. It is sawn with a hacksaw along the joint seam. The halves are connected back with bolts and sealant.

Pay attention to the tank. There are two types: collapsible and solid. If you have a Hotpoint-Ariston washing machine, for example, then most likely the tank is non-separable.In this case, it will have to be cut to get to the bearings. It is sawn with a hacksaw along the joint seam. The halves are connected back with bolts and sealant.

If the tank is collapsible, then it must be opened by unscrewing the bolts.

How to remove bearings

So, the tank is disassembled.

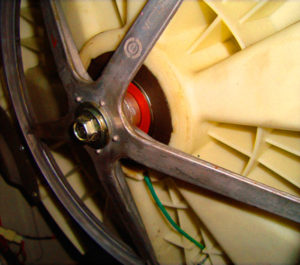

Now you need release the drum pulleywhich is held on with a nut. If the bolt doesn't want to come out, use WD-40. Next, the drum itself is removed by rocking the pulley housing.

Now you need release the drum pulleywhich is held on with a nut. If the bolt doesn't want to come out, use WD-40. Next, the drum itself is removed by rocking the pulley housing.

To separate the drum from the tank, the shaft is carefully knocked out. On both sides there are bearings in the seat that need to be knocked out.

After that, an inspection is made: which bearing is worn or broken?

If damaged, you will have to buy a new bearing and seal.

How to lubricate bearings in a washing machine? If there is no damage, then they are cleaned of dirt using WD-40, wiped with a cloth and then filled with grease. Such care for this part should be carried out once every five years. If the bearing is collapsible, then the protective cover is removed from it (it is convenient to do this with a scalpel) and treated with grease inside the part.

How to lubricate bearings in a washing machine? If there is no damage, then they are cleaned of dirt using WD-40, wiped with a cloth and then filled with grease. Such care for this part should be carried out once every five years. If the bearing is collapsible, then the protective cover is removed from it (it is convenient to do this with a scalpel) and treated with grease inside the part.

If the bearing is new, then it is not necessary to lubricate it, unlike the oil seal. This is done simply, the agent is applied in a uniform layer on the side that comes into contact with the sleeve. First, installation is carried out, and then oil seals.

Without knowledge and experience in such a matter, there is always a risk of damage drum, which will lead to a complete replacement of the washing machine. But, despite this, it is quite realistic to cope on their own.