The first to start developing washing machines was the notorious LG company, which, in addition to many interesting washing programs and additional functions, patented a direct drive.

The first to start developing washing machines was the notorious LG company, which, in addition to many interesting washing programs and additional functions, patented a direct drive.

But sometimes even such high-quality equipment can fail.

Washing machine direct drive

Mechanism Meaning

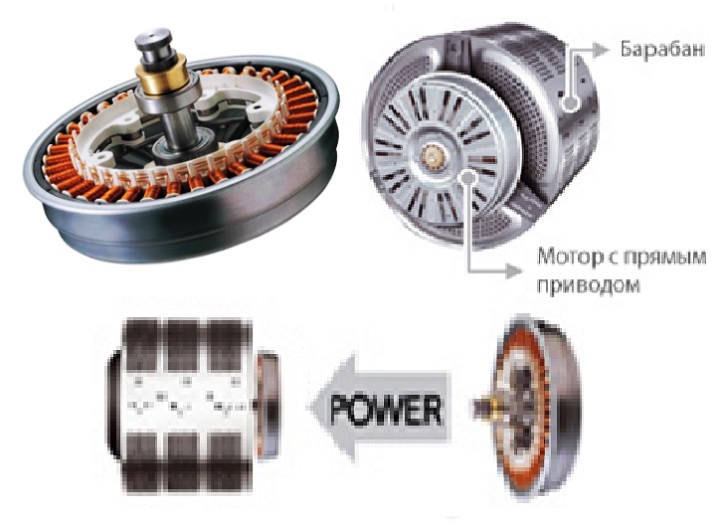

The design of such an engine transfers action to the rotor due to the air gap, which completely eliminates the possibility of wear of moving elements.

Direct drive is recognized as the most reliable electric motor.

The drive is the main structural element of any washing device. At the moment, direct drive and its device are used in the manufacture of their models of washing machines by manufacturers such as LG, Whirlpool, Sears and many others.

Differences between direct drive and other converters

Less noise

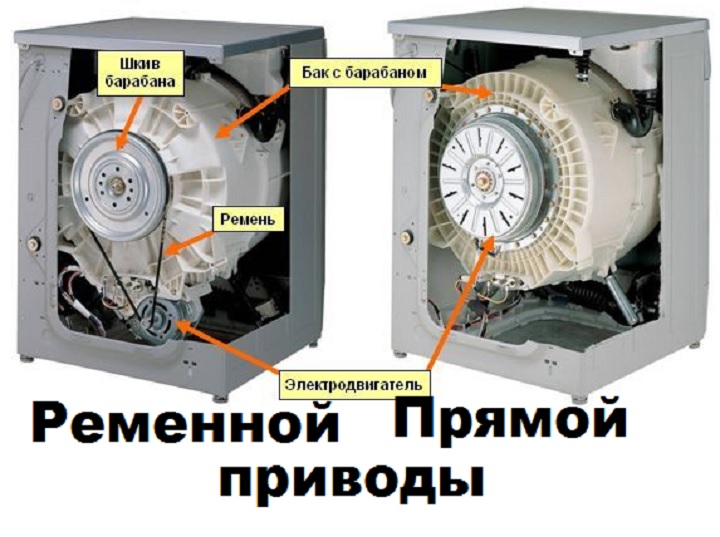

In conventional washing machines, a belt-type drum rotation transmission is common.It turns out that in such devices the drum is fixed on belts that provide the transmission of torque from the shaft.

The most vulnerable part of this system are the belts, which wear out from time to time and need to be completely replaced. In addition, washing itself and spinning in belt-driven washers are accompanied by a high level of noise and vibration.

The main distinguishing feature of washing machines that are equipped with direct drive is the complete absence of any brushes or belts in the motor, which are called contact nodes.

More things

With more cabinet space and a more powerful washing machine motor, direct drive models are different in that they can load more items than non-direct drive analog washing machines.

Uniform cleaning of things

In conventional washing machines, the washing process is concentrated on things that are located at the bottom of the drum, while in direct drive washing machines, dirt is removed by rotating the drum back and forth.

Design features of the device

In direct drive washing machines, the motor is attached to the drum without a belt or pulleys, and a special clutch is used instead, which plays the role of an electromotive device for the gearbox.

The absence of unnecessary transmission elements in such models makes it more compact.

In many cases, direct drive washing designs have a three-phase brushless motor.Its components are the rotor (permanent magnet) and the stator, which is equipped with 36 inductors.

The rotor is attached to the drum shaft, and the permanent magnet shaft is also the shaft of the washing drum. The engine is controlled by sending meanders from the electronic module.

Direct drive. Advantages and disadvantages

Advantages of direct drive

- In the design of the direct drive washer, the number of fragile parts and wear parts is much less than in devices with belt transmission. That is why LG is so confident in the quality of its equipment that it gives a 10-year warranty on such an engine.

- Of the sounds familiar to all of us that Direct Drive washing machines can make, you will only hear the measured rustle of laundry in the drum.

- Due to the fact that belt drive technology is not used, the stability of the device is significantly increased. Thanks to the use of direct drive in washing machines, the operation of the drum is as balanced as possible.

- Such engines do not need constant maintenance. maintenance and regular lubrication.

- Direct drive machines can automatically detect the load level on the drum and the weight of the laundry, which will allow you to choose the best power and avoid wasting water and electricity. So, savings due to this technology sometimes reach up to 30%.

Cons of direct drive

High cost washing machines

One of the disadvantages of direct drive washing machines is the high price. In this price range, there are many simple and reliable models from many other manufacturers that have proven themselves in the home appliances market.

The high cost in such models is due to the very complex design of the module, which is necessary to control the operation of the electric motor.

Dependence on good electricity

Direct drive in washing machines makes the device more vulnerable to power surges.

Direct drive in washing machines makes the device more vulnerable to power surges.

In this case, in order to insure yourself from expensive repairs, we advise you to immediately install a voltage stabilizer.

Fluid in stuffing box

Leakage can be avoided by regularly replacing the seal.

In direct drive washing designs, there is a small chance of liquid getting into the stuffing box.

Noise

Some users complain about the loud noise when draining and taking water during washing.

Rapid bearing wear

Sufficiently close arrangement of bearings and the complete absence of a pulley increases the load. So they will wear out faster, and from time to time you will have to replace them, which, as we said, is quite expensive.