If you, turning the switch, notice that the centrifuge does not turn on in your semi-automatic washing machine, do not despair!

If you, turning the switch, notice that the centrifuge does not turn on in your semi-automatic washing machine, do not despair!

Causes of a non-working centrifuge

There is several reasons that cause the problem:

- Damage to the safety sensor.

- Brake pads.

- Timer malfunction.

- Electrical damage.

- Other causes of malfunctions.

Safety sensor damage

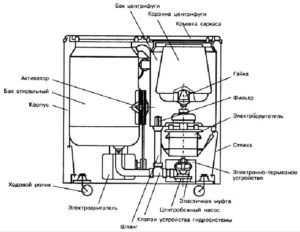

Some models, for example Daewoo (Daewoo) or Saturn, a sensor is placed on the door that closes the centrifuge tank. It is needed in order to disable the launch. To get to it, you will need to remove the top panel of the washing machine - under it there is a sensor with 2 contacts that need to be treated with a cotton swab dipped in alcohol. You do not need to scratch the contacts with a knife or clean them with sandpaper. Then you need to check the operation of the sensor. The contacts must close when the cover is closed.

Some models, for example Daewoo (Daewoo) or Saturn, a sensor is placed on the door that closes the centrifuge tank. It is needed in order to disable the launch. To get to it, you will need to remove the top panel of the washing machine - under it there is a sensor with 2 contacts that need to be treated with a cotton swab dipped in alcohol. You do not need to scratch the contacts with a knife or clean them with sandpaper. Then you need to check the operation of the sensor. The contacts must close when the cover is closed.

Brake pads

Brake shoes are installed under the centrifuge, and thus slow it down when opening.

The pads are connected to the cover with a cable. When the lid is opened, the cable is taut and

pads wrap around the part of the engine that rotates. Thus, the centrifuge stops.

It is necessary to open the rear wall of the SMP and check how the cable is tensioned so that the pads do not touch the engine when the door is closed, since touching the brake pads can prevent the electric motor from starting.

Fault in the timer

In most semi-automatic washing machines (SMP), the timer is located under the top panel of the device. It can be repaired by cleaning the contacts.

In most semi-automatic washing machines (SMP), the timer is located under the top panel of the device. It can be repaired by cleaning the contacts.

There are many tips on how to remove the panel, as washing machines from different brands are designed differently.

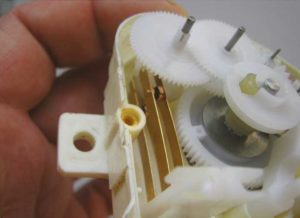

After you remove the top panel, you will notice a device that resembles a watch with gears.

Inside this device are contacts that can burn out with a long service life. The reason is soot, which does not pass current.

Inside this device are contacts that can burn out with a long service life. The reason is soot, which does not pass current.

It is necessary to disassemble the timer very carefully, since the cover of this mechanism also serves to attach gears to it. Having unscrewed all the screws, it must be removed so that the gear wheels do not fall out when opening. If you are worried that you will not be able to open the lid carefully, then it is better to play it safe and take a picture of the entire mechanism. After removing the cover, you will notice the contacts. They need to be wiped with alcohol, just like in the sensor.

Electrical winding damage

This can be checked with a tester, that is, a measuring device. Here are three steps on how to do it.

First, we find the ends of the wires that come out of the electric motor. There are usually three wires: the first is common, the second is the one that leads to the starting winding, and the third leads to the working winding. Usually, the common wire is marked with the letter “N” and made blue.

First, we find the ends of the wires that come out of the electric motor. There are usually three wires: the first is common, the second is the one that leads to the starting winding, and the third leads to the working winding. Usually, the common wire is marked with the letter “N” and made blue.- It is necessary to set the resistance test on the device, and measure it between the common wire and one of the other two, for example, red. If the resistance readings of the device are present on the screen, then everything is in perfect order with this winding.

We do the same with another pair, with a common and, say, a white wire. Then we measure the resistance and note the readings of the device. If there is no resistance, then this means that the winding has burned out. That is, the reason that the centrifuge does not work in your semi-automatic washing machine is a malfunction of the electric motor.

We do the same with another pair, with a common and, say, a white wire. Then we measure the resistance and note the readings of the device. If there is no resistance, then this means that the winding has burned out. That is, the reason that the centrifuge does not work in your semi-automatic washing machine is a malfunction of the electric motor.

In this case, there are two options: buy and install a new motor or hand over the old one for rewinding.

Other causes of centrifuge malfunctions in a semi-automatic machine

let's consider the most common causes of failure in the spin system.

The motor hums loudly, but the spin does not turn on. This means that the belt that connects the centrifuge and motor pulleys has broken or jumped off.

The motor hums loudly, but the spin does not turn on. This means that the belt that connects the centrifuge and motor pulleys has broken or jumped off.- During prolonged use of washing machines, it is possible wear of the rubber bushing of the diaphragm. A large gap between the parts will prevent the spin from turning on. For the washing machine to work, the bushing needs to be replaced.

- If you checked the electric motor and made sure that it is working, then it is possible the reason is a faulty thermal relay, or in a step-down transformer. These parts cannot be repaired and are replaced with new ones.

- It would also be useful to check whether small things are wrapped around the motor shaft. They can fly out during the spin cycle and get into the middle of the washing machine.

- Laundry unevenly stacked inside the spin dryer , can cause it to wobble and prevent it from starting.

- If the activator spin motors do not work, it would be nice to check fuse, which is located in the middle of the washing machine behind the back panel. You can also check the electrical plug (contacts).

However, if you carefully follow our advice, carefully and without haste to perform the necessary actions, then you will be able to repair their own washing machine, without outside help. This is especially true for the repair of a centrifuge in a semi-automatic washing machine.