Not every buyer knows the device of an automatic washing machine pump and its working features, while no one knows that the pump is considered one of the main and important elements of the entire washing structure.

Not every buyer knows the device of an automatic washing machine pump and its working features, while no one knows that the pump is considered one of the main and important elements of the entire washing structure.

We will help you figure out what these pumps consist of, their varieties, as well as differences in performance and maintenance.

The principle of operation of the washing machine pump and pump

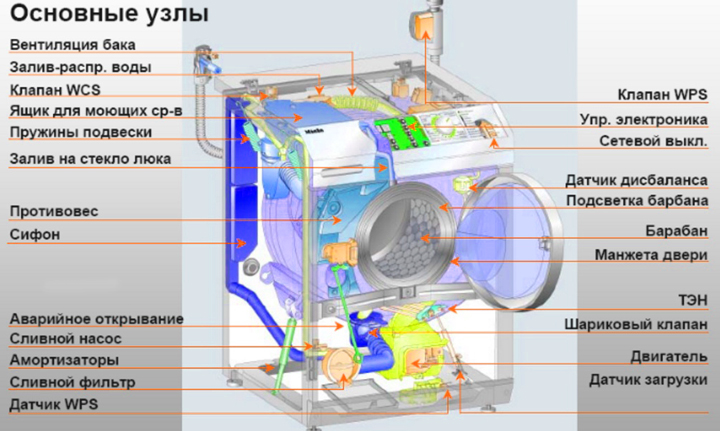

To date, all existing washing machines type automatic water comes by itself, that is, under pressure from the tap, to which the structure is attached.

To date, all existing washing machines type automatic water comes by itself, that is, under pressure from the tap, to which the structure is attached.

When the owner selects a specific command from the programs provided by the washing machine, a special magnetic valve that allows water to pass through opens in order to let the required amount of water into the drum.

As soon as the water enters the washing machine, it passes through all the patches with detergents, mixes along the way, and then enters the drum, during the entire washing process the water will be in it.

As soon as the water enters the washing machine, it passes through all the patches with detergents, mixes along the way, and then enters the drum, during the entire washing process the water will be in it.

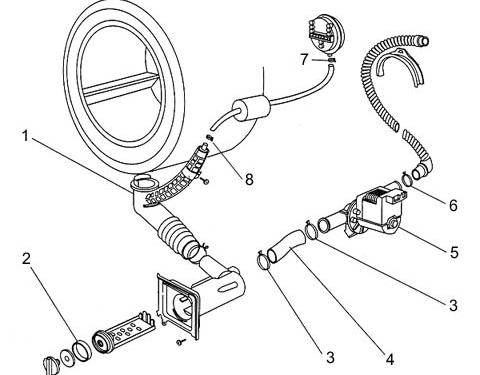

After the wash is over, all this used water enters the pump through a special hose.

water pump in tandem with the pump, it begins to pump out the used water from the drum into the sewer hole through the drain hose, this process begins after a special signal from the washing machine system and will continue until the water completely disappears from the tank.

water pump in tandem with the pump, it begins to pump out the used water from the drum into the sewer hole through the drain hose, this process begins after a special signal from the washing machine system and will continue until the water completely disappears from the tank.

Exactly the same process will occur in the rinse mode, however, already without a variety of detergents and various conditioners. Spin mode occurs with the same participation of the pump and the pump.

Pump device

The pump of the washing machine is called a small power asynchronous motor, which is equipped with a magnetic rotor, the rotation speed is about 3000 rpm.

Modern high-rise SMAs have only two types of pumps:

- Drain;

- Circular;

Drains pump out dirty water after the completion of the washing process, circular ones are responsible for the circulation of water in the washing and rinsing modes. Other less expensive washing machines have only drain pumps.

Drains pump out dirty water after the completion of the washing process, circular ones are responsible for the circulation of water in the washing and rinsing modes. Other less expensive washing machines have only drain pumps.

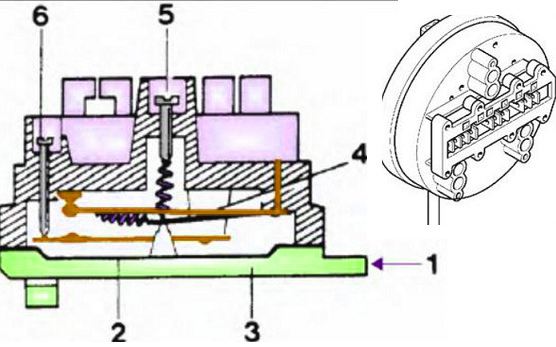

In its design, the pump (drain) rotor is somewhat similar to a cylindrical magnet.

The blades (which are fixed on the rotor axis) are deployed at an angle of 180 degrees to it.

When the drain device starts, the rotor comes into play first, after which the blades begin to spin. The core of the engine is equipped with two windings that are connected to each other. Their resistance together is about 200 ohms.

If you raise a conversation about low-power washing machines, then their external fitting will always be located in the middle of the case.It has special valves (rubber) of reverse action, which do not give water a chance to get into the tray of the washing machine from the drain tube.

Under the pressure of the liquid, the valve opens, and when the pressure from the water supply network stops, the valve immediately closes.

Other drain pumps other types allow fluid to flow in only one predetermined direction.

Other drain pumps other types allow fluid to flow in only one predetermined direction.

In such designs, in order to prevent gravity flow of the liquid, special cuffs are used for sealing. These cuffs don't give water a chance to get in. bearing. The shaft (rotary) in such a device will pass through the main collar sleeve, which will be equipped on both sides with corrugations and crimping from a special spring ring.

Operating rules

If you properly care for the pump for an automatic type washing machine, then its service life will last an average of about 10 years.

In order for this period not to decrease, you need:

Provide clean water to the washing machine (it is necessary to check the pockets in your clothes before washing for the presence of foreign objects and remove them, it is also better to remove pieces of dried dirt before putting the thing in the drum);

Provide clean water to the washing machine (it is necessary to check the pockets in your clothes before washing for the presence of foreign objects and remove them, it is also better to remove pieces of dried dirt before putting the thing in the drum);- Monitor health and safety filters;

- Do not let scale appear (use special tools for this);

- Completely empty the drum of water at the end of the washing process (wait until the water disappears from the tank to 100%).