The most unpleasant breakdown in a washing machine is a malfunction of bearings, seals, accompanied by a rattle, noise or whistle. The fact is that the process of repair and replacement is very laborious, since you will have to completely disassemble the washing equipment. But even that is not a big problem.

The most unpleasant breakdown in a washing machine is a malfunction of bearings, seals, accompanied by a rattle, noise or whistle. The fact is that the process of repair and replacement is very laborious, since you will have to completely disassemble the washing equipment. But even that is not a big problem.

The difficulty lies in disassembling the tank of the washing machine. Of course, if you have a guarantee, you should not take on such work yourself, but if the service center refused to help, there is nowhere to go. Failure is most often associated with the presence of a non-separable tank in the washing machine model.

There is a lot of information on the Internet about how disassembling the drum of a washing machine looks like, and there is a lot of thematic and video material. After reading and viewing, many washing machine users are confident in the success of the process.

In fact, everything is not so beautiful because of the many nuances, without knowing which you can spoil your assistant so that not a single specialist will take up the job.

So, to get to the bearings, you need to disassemble the drum of the Kandy, Zanussi washing machines, lg and other models. But it still needs to be reached. To do this, you will need to get almost all the parts, otherwise they can be damaged in the process of working with the tank or they will simply interfere with its extraction.

Tank disassembly rules

In the process of work, do not forget that:

The tank with the drum comes out of the washing machine very carefully. Most modern tanks are made of plastic, and this material is subject to the slightest mechanical stress. You may need the help of a friend when removing the tank.

The tank with the drum comes out of the washing machine very carefully. Most modern tanks are made of plastic, and this material is subject to the slightest mechanical stress. You may need the help of a friend when removing the tank.- If your tank is non-separable, it will have to be sawn. Before this process, it is recommended to drill many, many holes along the seam with a thin drill to reassemble the part. In this way, you will avoid misalignment of the halves and ensure a good seal. Stock up on sealant.

When cutting the tank, it is forbidden to make a bevel, even a couple of millimeters, to the side.

When cutting the tank, it is forbidden to make a bevel, even a couple of millimeters, to the side.- The screw that holds the drum pulley cannot be unscrewed without effort. But, excessive diligence is likely to be able to break the head, providing this with unnecessary problems.

- The rear part of the part can be removed from the shaft by light blows on it.

- If a bearing stuck, a car puller can come to the rescue. It is allowed to heat it with a blowtorch before removing it.

What you need to disassemble the drum

A set of tools for repairing and replacing bearings is simple. Basically, all this is in every house or garage. Last but not least, a neighbor. Would need:

Screwdriver Set;

Screwdriver Set;- a set of keys;

- car puller;

- blowtorch or gas burner, although this option is not the best due to the lower heating temperature;

- drill with drills;

- wire cutters;

- wooden block;

- hacksaw with blades;

- copper hammer;

- WD-40 lubricant.

How to disassemble the washing machine drum

Collapsible tank with drum

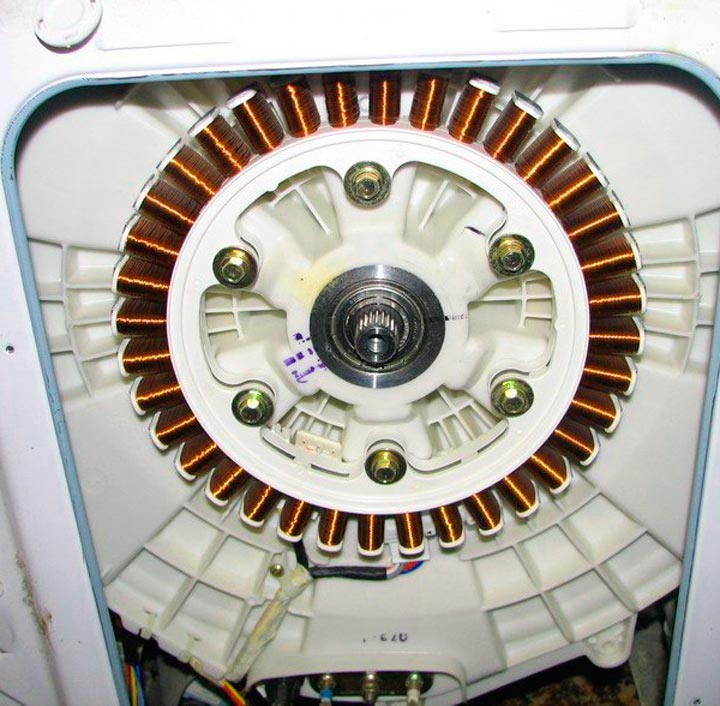

The collapsible tank consists of two halves connected by bolts using sealant or sealing gum.

The collapsible tank consists of two halves connected by bolts using sealant or sealing gum.

Disassembly drum washing machine looks like this:

- Taking a wooden block, you need to lock the drum pulley while the hatch should be located below.

- It is necessary to unscrew the bolt that secures the pulley to the shaft. In this case, you need to use a head of the desired size with a ratchet.

- The bolts connecting both halves of the tank are unscrewed with a key, after removing the pulley.

- After that, hitting the shaft lightly, the rear part of the part is removed.

- The bearings are pulled off, if difficulties arise, then they are heated with a blowtorch and removed with a puller.

How to disassemble a non-separable drum of a washing machine

It is difficult to cut with a hacksaw for metal, it often gets stuck and breaks. But, despite this, it is considered the most optimal and proven option. Experts advise wrapping one edge of the hacksaw with electrical tape for the convenience of work, which will take at least 3-4 hours.

It is difficult to cut with a hacksaw for metal, it often gets stuck and breaks. But, despite this, it is considered the most optimal and proven option. Experts advise wrapping one edge of the hacksaw with electrical tape for the convenience of work, which will take at least 3-4 hours.

A hacksaw cuts so thickly that in the future it is problematic to ensure the sealing of the two halves.

The grinder is generally immediately excluded due to the high risk of damaging the part and deep penetration.

A jigsaw can help, unless there is a hard-to-reach area where you have to use a hacksaw.